Written in collaboration with Bryan McLaughling.

TL;DR

- Lithium batteries are widely used in modern devices such as laptops, smartphones, and electric vehicles due to their high energy density, lightweight, and long cycle life.

- It is important to charge lithium batteries properly to avoid safety risks and to maintain battery health.

- When using a lithium battery in a device, consider the placement of the battery and ensure that there is enough space for expansion when fully charged.

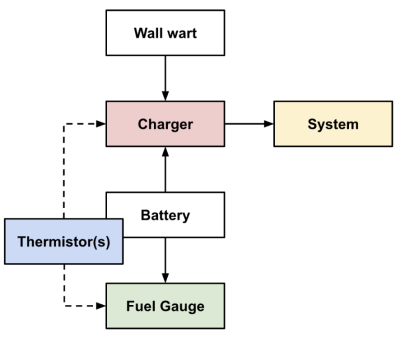

- The battery management system (BMS) takes care of the battery, including the charger, fuel gauge, and thermistor.

- Lithium batteries should be treated with care to avoid issues and ensure proper function.

What are they and why they’re so popular

You probably have a number of lithium batteries lying around you right now. Most modern devices, such as laptops, tablets, smartphones, smartwatches, portable speakers, headsets, mice, keyboards, smoke detectors, and even your Tesla car contain lithium batteries.

All of these products wouldn’t exist in their current form if it weren’t for lithium batteries.

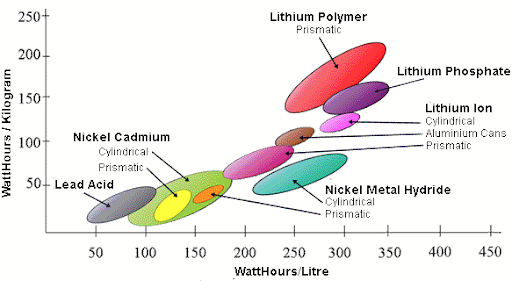

Lithium batteries are rechargeable batteries that use lithium ions as the main source of energy. They are lightweight, have a high energy density, and a long cycle life compared to other battery chemistries, making them popular in portable electronics, electric vehicles, and energy storage systems.

High energy density is the key advantage here. You wouldn’t carry your smartphone around if it weighed 10lb (4.5kg) or was the size of your laptop. Lithium batteries effectively enable phones that can fit in your pocket and be carried anywhere you want. After all, lithium is the lightest of all metals!

How to take care of them

“With great power, comes great responsibility” – Attributed to a lot of people

Only a few years ago, Samsung was forced to recall their Note 7 out of concern for exploding batteries. Consider that 2.5 million Note 7s were sold, and you get an idea of the financial impact on the company, plus the PR nightmare.

Teslas and e-bikes have been catching fire too, raising questions about the control electronics that keep these batteries safe. Recently, a single e-bike battery started a fire that consumed a whole supermarket in New York City.

How to charge them – safely

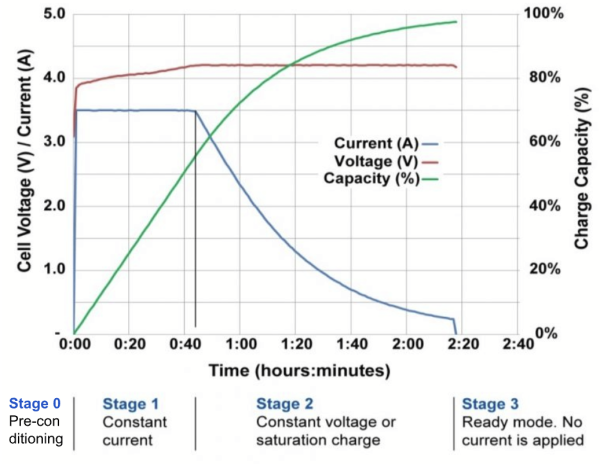

Unlike old-school lead-based batteries, which can be found in ICE cars, lithium batteries need to be charged with care. The charging circuit will employ what’s called a “charge profile”, similar to the one below.

Essentially, a dedicated charging circuit will first determine the battery status. In case the battery is deeply discharged, a proper pre-conditioning phase is a must to establish battery health.

Assuming the battery is healthy, charging can start at a high current level. This phase is called CC (constant current). Once the battery is ~60% charged, charging current will gradually decrease until the battery is deemed fully charged. This last phase is called CV (constant voltage), because the circuit will simply maintain the battery voltage constant while letting the current decrease exponentially.

This is why it comparatively takes a long time to charge from 90 to 100%: when the battery is almost full, the charging current is very low. Charging from 0 to 10% happens much more quickly, because the current is much higher.

To be fair, one could theoretically charge at a low, constant current for the whole charge cycle. However, that’d result in a much longer charge time. Most smartphone users would find that unacceptable.

When it comes to picking a charger IC for your lithium battery, we recommend industry leaders like Texas Instruments, Microchip, NXP, Analog Devices or Maxim Electronics.

Where to put them in your product

Should you decide to power your device with a lithium battery, pay attention to a few key details.

Where will the battery be placed? In most smartphones, for example, the battery is secured in the back, usually by means of strong double-side adhesive.

Double-check that the battery has enough space to expand when fully charged. Yes, lithium batteries will grow bigger when at 100% capacity. You can expect them to swell up to 10% of their initial thickness.

A mechanical engineer working with batteries must remember to include swell into their TA (tolerance analysis) and make sure they will have enough room around them. Otherwise, the device itself will deform when the battery swells, or worse yet the battery will suffer damage.

On the electrical side, there’s a whole other slew of challenges to keep in mind. We’re looking at them in detail in the next chapter.

Suffice to say that these batteries need to be treated with care, or else things will go awry.

Common control electronics – BMS

Open up any smartphone, and you’ll likely find components that take care of the battery itself. As a whole, that’s the BMS (Battery Management System) and it’s usually made of:

- Charger. This is the main chip that takes care of charging the battery (following the proper charge profile we already discussed). It requires an external source of power, which often comes in the form of a USB cable from a wall wart. The charger will make sure that power is always available to the smartphone, whether the battery is charging or not.

- Fuel gauge. Quite a fancy name, suggesting a combustion engine. Here the fuel is simply electric current. This chip specializes in measuring it to a high degree of accuracy. Often, the fuel gauge will “talk” with the charger as well, ensuring full monitoring of every charge and discharge cycle. Over time, the fuel gauge will get to know the battery and monitor key parameters such as SoH (State of Health) and SoC (State of Charge). As the battery degrades after years of use, the fuel gauge will take note and keep it going for as long as possible.

- Thermistor. A simple component, placed right on the battery that tracks its temperature. Battery temperature increases during charge and discharge, which is a normal phenomenon. Ideally, temperature should stay within 60 – 95 F (15-35 C). However, this range can stretch 20 F on each side and you’re still in a safe zone. Anything outside of that, and it’s better not to charge the battery. Discharge at low temperatures can still happen, however it will drain the battery much faster than it normally would.

Where do they come from?

Lithium is available, though it isn’t exactly easy to extract. Concerns about mining and metal availability should play into your supply chain strategy, should you need lithium batteries in high volumes.

Tesla went as far as considering mining its own lithium, given how much material they need to build their cars. We don’t expect Fusion Engineering Group going to that length in the near future.