Written in collaboration with Maggie Durocher.

TL;DR

- To mitigate supply chain woes, companies should diversify suppliers, increase inventory levels, look for alternative products or materials, improve forecasting, and build solid relationships with suppliers.

- Effective BOM management is crucial to identify sole-sourced components and find second or third sources for every passive component.

- Buying more parts in advance and storing them can reduce the risk of stockouts and reduce BOM cost.

- Just-in-time inventory management is not always effective for SMEs, who may not have leverage on suppliers.

- Drop-in replacements, dual overlapped footprints, and other strategies can shield customers from supply chain headaches.

If you work in an industry where manufacturing is a central process, you’ve likely had to deal with supply chain shortages. The last two years have been particularly painful; even large companies have been forced to redesign their products when certain components go out of stock. This is never a good thing – it means incurring delays and additional costs, which eventually impact the bottom line. Worst case scenario, product launches may be scrapped altogether, burning a lot of funds for no positive outcome.

As Elon Musk found out himself, “The supply chain stuff is really tricky.” (he doesn’t mince his words).

It’s critical to insulate ourselves against the potential downsides of supply chain. That’s because of the huge factor that supply chain management plays in manufacturing a hardware product.

At Fusion Engineering Group we found that the following actions help mitigate or resolve supply chain woes:

Diversify suppliers

By having multiple suppliers for the same product or component, companies can reduce the risk of being affected by a shortage caused by a single supplier.

In the consumer product space, this translates into effective BOM (Bill of Materials) management. The BOM lists all the individual components needed to build a specific product, along with their main characteristics.

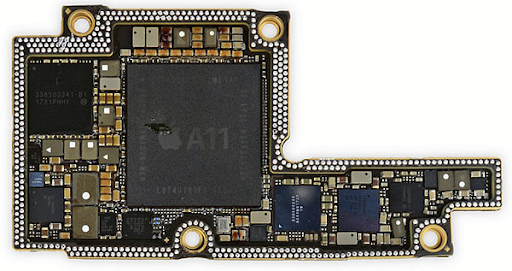

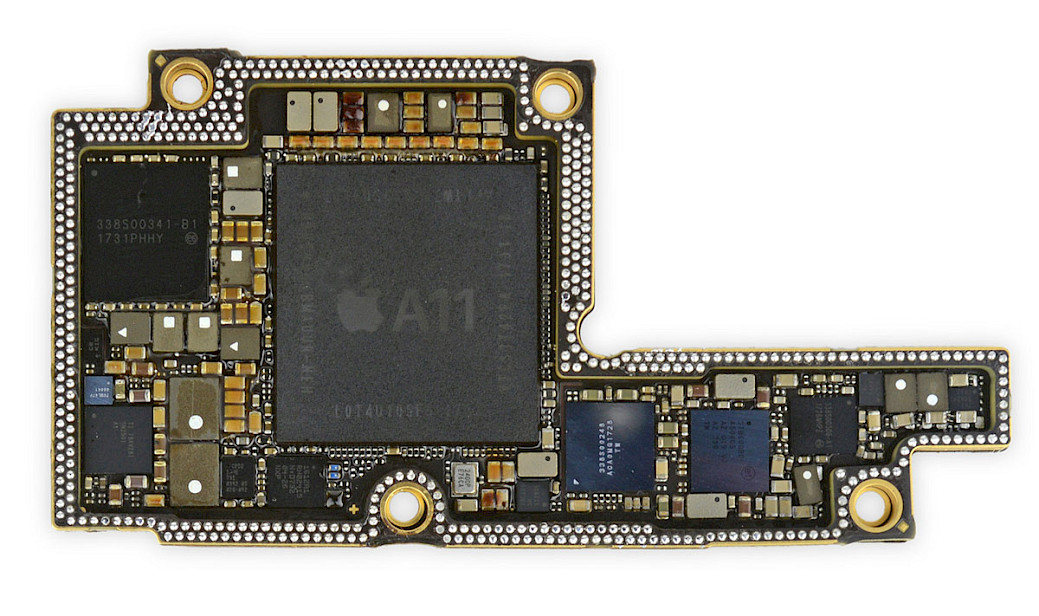

For a modern smartphone, the BOM can have more than 1000 lines. The PCB alone, as you can see from this picture, is packed tightly with a slew of tiny parts. The unavailability of just one of these critical components can cause cascading delays across the entire project.

Here below we can see a BOM extract from a Chinese PCB supplier, where each line describes a component on the PCB.

By having a hard look at your product BOM, you can identify components that are sole-sourced vs single-sourced. A sole-sourced component can only be obtained by a specific supplier. It may even have been designed as a custom part, making it impossible to buy from a different supplier.

In today’s environment, it’s wise to keep your options open. If one supplier bites the dust, you should have another one ready to replace it. Question every sole-sourced part in your BOM, and see if you can replace it with a part more widely available.

On a typical circuit board, you should aim for having at minimum two (and hopefully more ) sources for every passive component. For active components instead, second-sourcing decisions are more complex.

While the design process moves on, review the BOM on a weekly/monthly basis: this will help you catch problems early on and adjust your procurement strategy accordingly.

Increase inventory levels

If money is available, it might be wise to simply buy more in advance (and possibly score a discount). Parts would then be stored at a trusted partner location, or simply kept at your company warehouse, should you have one.

Another strategy worth mentioning is JIT (just-in-time) inventory management, where inventory is kept to a minimum.

JIT is all the rage these days. No reason to jump on the bandwagon though. JIT has its own challenges, particularly for many of our clients that are SME. Such a company typically doesn’t’ have lots of leverage on suppliers, exacerbating the common issues found with JIT:

- Heavy Dependence on Suppliers

- Vulnerability to Disruptions

- Increased Cost of Inventory

- Risk of Stockouts

JIT is effective when implemented correctly, particularly in industries with stable demand and well-developed supply chains. That’s usually not the case for SME.

More often than not, money is tight and buying more in advance is not an option. In that case, here are a few steps that SME can follow:

- Automate the sourcing process to accurately track inventory level and material availability

- Invest in data analytics to improve material management and to mitigate the risks

- Implement a logistics contingency plan to avoid large scale disruptions

Bottom line result: an optimal inventory level without overly stress on the cash flow and an increased level of efficiency.

Look for alternative products or materials

There are multiple strategies we’ve been using to shield our customers from supply chain headaches:

- Drop-in replacements. These parts can be used while keeping everything else the same. Say one USB connector isn’t available anymore, but you found one that’s essentially the same. Just edit the BOM with the new part and you’re good to go.

- If the same part comes in different footprints, allow for both of them on the PCB. This way, they can be swapped out while keeping firmware almost identical. This trick can save you time and money down the road. However, it could make the board bigger

- Allow for dual, overlapped footprints on a PCB, while not enlarging the board itself. Compared to the point above, this strategy lets you choose parts from different vendors. The pool of available components gets larger.

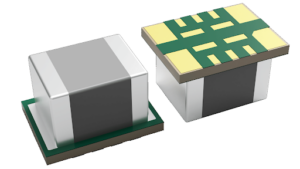

- A subsystem made of individual parts might be replaced by an integrated module that performs the same function. This is the case for certain voltage regulators. Incidentally, you may even reduce board size by using an integrated module like the examples below.

Overall, foster resilience: build flexibility into the supply chain by having backup plans in place for disruptions and contingencies.

Improve forecasting

As product development progresses and gets closer to mass production, market conditions may change. This in turn will change demand for your product.

A typical smartphone’s development cycle takes about 2 years. There are a lot of things that can happen in that timeframe.

Timeline and project management is key here. This is a broader topic for another blog post (stay tuned). Suffice to say: your suppliers will enjoy working with you and give you preferential treatment if you can stick to your schedule.

Build solid relationships with suppliers

Transparency is key. As per the last point above, develop strong business relationships where both sides are invested in the project and want to make it a success.

A supplier that trusts you will advise ahead of time about potential shortages, so you can plan accordingly. The last thing you want is to be left out to dry.

Lastly, make sure you use the chips you buy. Here’s why:

Chip supplier XYZ will be happy if you buy ICs from them, and will be even happier if you actually ship high-volume devices with their ICs in them. Such a device will undoubtedly be torn down by some enthusiasts, in turn giving visibility to supplier XYZ.