Why bother reviewing?

“After we sit on a design for too long, it looks perfect even if it’s not” – Andrea Fusi.

Even the best engineers make mistakes. That’s why we love to have other top engineers review our design: there’s always something to learn from having a second opinion.

Let’s see how critical design reviews can be with an example: making a prototype PCB.

Imagine we’ve designed new PCBs and had our engineers test them. Unfortunately, they found one mistake we should have noticed. Now, we have to fix it, hold another review meeting, and rebuild the PCBs. This means a 6-8 weeks delay, even with extra fees and working round the clock. The whole project schedule gets affected. The mechanical engineering team needs proper PCBs, and the firmware team can’t test on faulty boards.

Building extra PCBs for a typical consumer product costs around $10,000 – $20,000. It might sound like a lot, but it’s much less than the time and schedule impact. The total damage could quickly go over $50,000.

A mistake like this could have been avoided with a well-executed design review. In our experience, design reviews are crucial in preventing costly blunders and keeping our projects on track.

This blog post will emphasize the importance of design reviews in hardware development. We’ll explore how they can save time, money, and effort while ensuring top-notch quality. Gain valuable insights to optimize your engineering process and avoid project pitfalls:

When should we review?

How mature the design needs to be before doing a review? Well, it depends on what you’re reviewing.

For example, a BOM scrub should first be done when the design is only 25% complete but you’re also confident that you’ll use the components you selected.

Conducting a design review before crucial project milestones, such as “Layout Design Completed” or “Schematic Design Completed,” is typical. However, there are nuances to be mindful of:

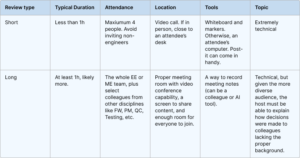

Design reviews come in two flavors:

- Long, formal reviews

- Short, informal reviews

Most team members actively participate during long reviews and offer insights on design details and choices. Additionally, other departments may have their representatives as observers in these meetings, often to address internal considerations or ensure inclusivity. These meetings may involve 10+ attendees. If it sounds political, it’s because it can be.

Design reviews can also be more informal, particularly in the first phases of a project. When things are moving fast, it doesn’t make sense to tie up two hours of everybody’s time. A quick sync with a fellow engineer will suffice.

The thing to understand here is that both types should be considered a design review and have value. Just because you and another engineer are meeting to discuss the design files doesn’t mean it’s not a design review. Framing even these little meetings as such will lend them to being more productive and insightful.

To use everyone’s time efficiently, take clear notes during the meeting and assign action items before it ends. Doing this ensures accountability and progress in addressing any issues identified, making the design review process more streamlined and collaborative. Moreover, there are design reviews that do not even require meetings. For example, you can do a BOM scrub independently – no need to add one more meeting to our busy calendars.

Who got time for this?

More often than not, there’s little time to set aside for design reviews, if any at all. This is puzzling because design reviews are among the most important activities in the product development cycle.

Skipping design reviews gives the illusion of saving time, especially with the time-consuming processes in manufacturing: like the 6-week duration for plastic injection part casting or 4+ weeks for PCB fabrication.

From many years of experience, we found it best to include design reviews in the project schedule. That way, there’s time budgeted for it, and the C-suite accepts we’ll invest time in it.

What to review?

After years and years of hard-thought lessons, we’ve identified the must-have of any design review list for a hardware product. Download this list for free and distribute it amongst your friends and colleagues. Over time, we hope the list molds to fit your specific use case – and we’d love to hear about any change ideas you’ve got.

In conclusion, design reviews play a vital role in hardware development, allowing teams to catch and rectify potential errors quickly. Projects can avoid costly delays and ensure successful outcomes by incorporating comprehensive review meetings and clear action items. Emphasizing the importance of design reviews throughout the development process is key to achieving top-notch quality while saving time, money, and effort.

At Fusion Engineering Group, we’re proud of how we conduct design reviews. If you’re interested in a free design review for your project, get in touch – we’d love to help out.